IKT LinerReport 2020: CIPP liners meeting target values at six-year low

Sign up for our free Online Seminar on 14th April: The IKT LinerReport!

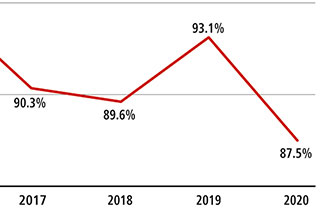

But, even when looking at the four test criteria individually, the 2020 results are the lowest in six years. In 2018, the mean results for wall thickness were slightly lower than in 2020; otherwise, all the mean results from 2015 to 2019 were better than those of 2020.

2020 test results weaker than 2019

Figure 1: Percentage of CIPP liner samples that met their target values for all four test criteria (click to enlarge)

All four test criteria must be fulfilled

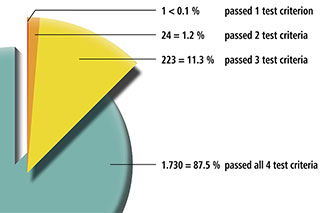

It makes little sense to consider the test criteria individually for a CIPP liner sample. Rather, it is important to a network owner that for each sample all four test criteria are fulfilled, according to the declared or designed target value for that installed liner. Only then can they be very certain that the liner that was delivered and installed actually achieved the material characteristics promised.

Of the samples for which all four target values were provided for all four tests:- < 0.1% passed only one test criterion

- 1.2% passed only two test criteria

- 11.3% passed three test criteria

- 87.5% passed all four test criteria

Top performers: the “100% Club”

A high-quality liner must fulfil all four test criteria simultaneously. In most cases, the target values against which test results were compared derive from declared values in a product approval and in a few cases they were provided by the site-specific static calculations from the customer’s specification. In 2020, five out of 27 rehabilitation companies achieved the target values in all four test criteria for all their samples (the previous year it was three out of 23), so they meet the quality requirements in full at each of their installation sites.

This “100% Club” of 2020 comprises:- Bluelight (D) with the PAA-F-Liner

- Hamers Leidingtechniek (NL) with Alphaliner

- Jeschke Umwelttechnik (D) with Alphaliner

- Kanaltechnik Agricola (D) with Brandenburger Liner 2.5

- Umwelttechnik und Wasserbau (D) with Brandenburger Liner 2.5

In Figure 3, these companies receive a star for each year that they have been in the “100% Club”, to highlight their achievements.

As a testing institute, we can only report the findings, but cannot speculate about the reasons for these developments, as we are unable to interpret them in an evidence-based manner. One thing is clear, however: despite the very high technological development of the CIPP lining method, despite its position as the leading renovation method and despite intensive staff training, an ever-higher level of samples meeting target values in tests is not a given. On the contrary, it has been shown that these can also go down. Therefore, strict application of quality controls continues to be necessary, both on the rehabilitation sites and in the testing laboratory.

download full IKT LinerReport 2020

to the download page for all IKT LinerReports

Contacts

Iain Naismith, PhD

T: +44 (0) 7983 605219

E-mail: naismith@ikt.institute

Barbara Grunewald, M.Sc.

T: +49 (0) 209 17806-40

E-mail: grunewald@ikt.institute

Rehabilitation contractors and liner systems matter

Six of the 27 rehabilitation companies in this year’s LinerReport appear more than once, as they submitted two or three different CIPP liner systems. The other 21 appear with one type of CIPP liner system. The six companies with multiple CIPP liner systems achieved differing test results with different liners. This shows that the success of the rehabilitation depends not only on the rehabilitation company, but also on the CIPP liner system used.

No Comments