Testing of plastic materials

The IKT test centre is accredited in accordance with European/ISO Standards (DIN EN ISO/IEC 17025) for selected mechanical/technological tests on polymeric components used in pipe/CIPP liner systems and samples of GRP laminates.It is designated by the German Institute for Construction Technology (DIBt) as a test centre for elastomeric seals for use in waste-water sewers and pipelines.

It is also a recognised supervisory body for CIPP liners and glass-fibre-reinforced plastic (GRP) short-liners.

Climate-controlled plastics laboratory

The IKT’s test centre provides the following services in its climate-controlled plastics laboratory:- Materials tests in accordance with the relevant standards

- Quality Assurance product tests

- Initial and validation tests of products

- Tests for national technical approvals (DIBt approvals)

- Individually tailored special tests

DSC analysis of plastics samples

European/ISO Standard: DIN EN ISO 11357

- Differential scanning calorimetry (DSC) is a procedure for the determination of the thermal properties of polymers and polymer blends (thermoplastics, thermosets, elastomers).

- DSC analysis is used at IKT primarily for the determination of the glass-transition temperatures of epoxy resins.

- DSC analysis can be used for determination of the following properties:

– Glass-transition temperature

– Melting and crystallisation temperature

– Specific heat capacity

– Reaction enthalpy and rate

– Oxidation induction time (isothermal OIT)

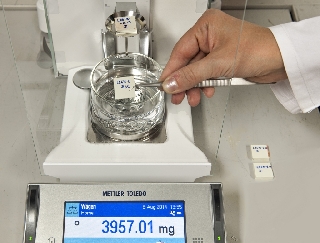

Determination of density

European/ISO Standard: DIN EN ISO 1183, Part 1

- The density of a plastic material indicates whether air bubbles (for example) are present as a result of errors during the production, blending and/or processing of a plastic.

- Density is determined using the immersion method.

- The test sample is weighed on high-precision analytical scales.

- The sample is then immersed in a prescribed liquid and weighed again.

- The density of the sample can then be determined from the results of the two weighing operations and the density of the prescribed liquid.

Determination of behaviour under exposure to liquid chemicals

European/ISO Standard: DIN EN ISO 175

- Plastics used in waste-water pipes must be able to withstand aggressive fluids.

- Test objects are exposed in relevant test fluids for 28, 90 or 180 days.

- Tensile strength, elongation at rupture and impact strength are then measured.

Testing of elastomers

- Determination of sealing width, contact-pressure distribution and maximum deformation, in accordance with European Standard: DIN EN 1916.

- Determination of compression set (ISO 815, Part 1).

- Determination of stress relaxation under pressure (ISO 3384, Part 1)

- Tear strength, tear resistance (DIN ISO 34, Part 1)

- Hardness tests

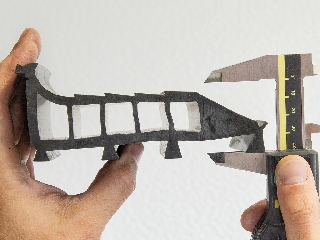

Tensile tests

European/ISO Standard: DIN EN ISO 527

- Tensile tests are used, for example, in the validation of the chemical resistance of plastics, since the results of this test disclose even extremely small changes in the material.

- Tensile testing of plastics supplies the data for a sample:

– Tensile strength (maximum tensile stress)

– Ultimate tensile elongation

– Ultimate stress

– Elongation at failure - It is also possible to determine the elastic modulus of a plastic material.

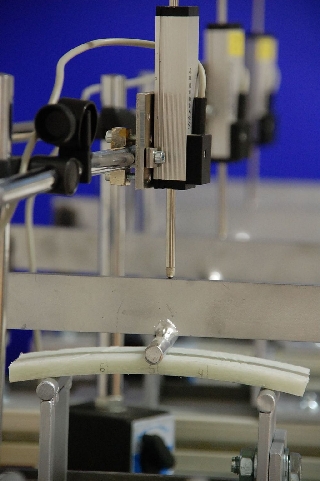

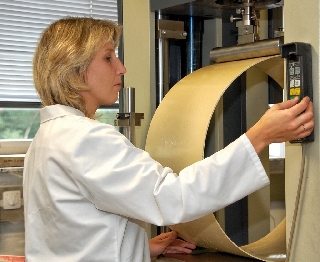

Three-point bending test

European/ISO Standard: DIN EN ISO 178

- The three-point bending test is used to determine the flexural properties of a sample of plastic.

- The three-point bending test supplies the data for:

– Bending stress at failure

– Flexural strength (maximum bending stress)

– Flexural strain at failure or at flexural strength

– Deflection

– Flexural modulus of elasticity

Testing of the creep behaviour of samples of plastic

European/ISO Standard: DIN EN ISO 899, Part 2

- The elongation (deformation) of a plastic exposed to a constant force becomes ever greater with time. This phenomenon is known as creep behaviour.

- Creep behaviour can be determined by performing a three-point bending test on small samples of the plastic.

- Precise knowledge of creep behaviour is important for the design of plastic structures.

Testing of plastic pipes

- Thermoplastic pipes

- Glass-fibre-reinforced thermoset plastics

- Determination of ring stiffness

- To European Standard: DIN EN 1228

- To European/ISO Standard: DIN EN ISO 9969

Determination of creep behaviour in plastic pipes

European Standard: DIN EN 761

- Plastic pipes are exposed to continuous stresses imposed (for example) by groundwater and soil loads.

- The deformation of a plastic pipe under exposure to a constant load becomes ever greater with time. This phenomenon is known as creep behaviour.

- Creep behaviour is taken into account in structural-analysis calculations (design) using the long-term characteristics (fifty years) for the modulus of elasticity.

- This long-term modulus of elasticity is determined by means of extrapolation from the results of the 10,000 h test.

- The test: Application of a constant load and measurement of pipe deformation across time (up to 10,000 h). Extrapolation to 50 years.

Contact

Dieter HomannDipl.-Ing.

T: 0209 17806-24

E: homann@ikt.de

Contact:

IKT - Institute for Underground Infrastructure

neutral, independent, non-profit

T: +49 (0) 209 17806-0

E: info@ikt.de

www.ikt.de

www.facebook.com/IKTonline

www.youtube.com/IKTonline