2019 IKT LinerReport: Seven Percent of Sewer Liner Samples do not Pass all Tests

The 16th Edition of IKT’s annual LinerReport summarises the test results from a total of 2,353 sewer pipe liner samples examined by the institute’s test centre during 2019. The IKT-LinerReport has an international scope, with rehabilitation companies from seven countries participating.

The samples submitted are evaluated against four short term tests. Pass/fail for each individual sample is determined by comparing the test result with the expected value for the installed liner, which is either the manufacturer’s declared value for the product or the value required by the client’s specification.

Download the 2019 LinerReport here

2019 test results

In 2019, most of the sewer liner samples test results remained at a very high level, compared with recent years, if the four test criteria are considered individually. For the modulus of elasticity and flexural strength tests, average pass rates improved slightly compared to the previous year: by +0.4 percentage points (pp) to 97.9% and by +0.8 pp to 98.2% respectively. The average value for water tightness is almost at the same level as in 2018: dropping slightly by -0.3 pp to 98.6%. Whilst, for wall thickness the results improved by +3.4 pp to 97.5%.read more about these four tests

Liners that passed all four test criteria

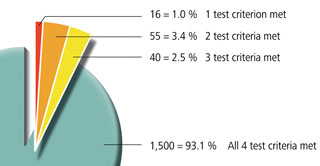

However, if it is assumed to be self-evident that a professionally installed sewer liner must meet its target values for all four test criteria, a poorer picture of sewer liner quality emerges. It is apparent that in 2019 only 93% of the samples, tested against all four criteria, passed all four test criteria at the same time. Some seven percent of the installed sewer liners did not do this and thus do not meet all requirements and specifications. In other words, one in fourteen liners does not meet all test criteria and fails at least one criterion.

Diagram 1 shows that of the 1,611 samples (two thirds of all samples) for which all four nominal values are available:- 93.1% pass all four test criteria,

- 2.5% pass only three test criteria,

- 3.4% pass only two test criteria, and

- 1.0% pass only one test criterion.

For one third of the samples (742) the target value for at least one test criterion was not provided, or part of the testing programme was not commissioned.

Positive picture put into perspective

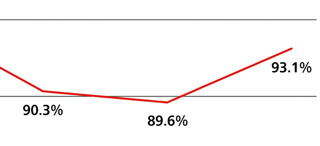

This puts into perspective the very positive picture apparent at first glance, since seven percent of the liners do not achieve the required material characteristics across all four test criteria. In the previous two years, the situation was weaker: then only 90% passed all tests and so one in ten liners did not meet all the requirements (see Diagram 2). This is a not inconsiderable rate for a rehabilitation procedure that claims to be the standard procedure for the rehabilitation of sewage pipes.A notable improvement in wall thickness

The improvement in the wall thickness results is remarkable: this test was passed by 97.5% of all samples tested, which is 3.4 percentage points (pp) more than in the previous year. Without exception, all samples made of needle felt carrier material (NF) have passed this test. NF liner performance improved by +2.6 pp to 100%. Liners made of glass fibre reinforced plastics (GRP) increased by +4.2 pp, with an average result of 97.2% passing, but remaining almost 3 pp below the NF result.In the last three years there has been an intensive technical discussion about the wall thickness of sewer liners. Advocates of higher minimum thickness requirements were opposed by those who believe that wall thicknesses of three millimetres and less can also be tolerated. The test results of the IKT LinerReport 2019 show that rehabilitation companies have successfully made efforts to comply with required wall thicknesses. This should have a positive effect in ensuring the long term performance of installed sewer liners.

The 100% Club

The 100% Club: companies who passed all tests in all criteria with all samples (Click on table to enlarge)

The companies in the “100% Club” of 2019 are:

- Hamers Leidingtechniek (NL) with Alphaliner

- Jeschke Umwelttechnik (D) with Alphaliner

- Kanaltechnik Agricola (D) with Brandenburger Liner

Diagram 3 shows the years in which these companies previously got a “100% Club” membership, highlighting their recent performance.

Conclusions: better results but still room for improvement

2019 was predominantly a good year for sewer liner quality, not only in Germany, but also in a number of European countries participating in this report. It is encouraging that, on average, better or equally good results were achieved compared with the previous year for almost all test criteria.

However, it cannot be overlooked that only very few rehabilitation companies manage to provide a very high performance throughout. These are the three companies in the “100% Club” that have passed all four test criteria for each of their samples. With a total of 23 rehabilitation companies whose sewer liner samples are included in the 2019 IKT LinerReport, there is undoubtedly still some room for improvement in quality.

Database for the 2019 IKT LinerReport

- Number of liner samples: 2.353

- of which: 2,072 were GRP liners and 281 needle felt liners

- Number of sewer liner systems included: 7

- Number of sewer rehabilitation companies: 23

- Minimum quantity of samples required: 25 liner samples of one type from five different construction sites per rehabilitation company

- Sample suppliers: 69% sewer network owners and 31% sewer rehabilitation companies

- Countries of origin: Belgium, Czech Republic, France, Germany, Great Britain, The Netherlands and Switzerland

The same applies to the proportion of sewer liner samples that meet all four test criteria at the same time. At 93%, this is not so impressive because it means that every 14th liner does not fully meet the quality requirements.

However, the four test criteria with their target values are there for a good reason: only if all four are fulfilled can clients assume that they have received a professionally installed liner, with good prospects of a long service life in the sewer. The rehabilitation companies as well as the liner producers have to make the same demands on themselves. Because only in combination can they achieve high sewer liner quality at installation sites and thus permanently consolidate the position of the sewer liner as the leading sewer rehabilitation method.

And in the future, in their own interest, clients should pay more attention to ensuring that they state the required target values for all four test criteria in their sample submission forms. So far, this is only the case in two thirds of the samples, with one third lacking information on the target values for some tests. It is therefore not possible to fully assess the performance of all the samples submitted for the IKT LinerReport.

Download the 2019 LinerReport here

IKT Test Centre for CIPP liners

Contacts

- Barbara Grunewald, M.Sc.

T: +49 (0) 209 17806-40

E-mail: grunewald@ikt.institute - Iain Naismith, PhD

T: +44 (0) 7983 605219

E-mail: naismith@ikt.institute