LinerReport

LinerReport

IKT’s impartial and independent Test Centre for Building Products has reported on the results of its CIPP liner tests every year since 2004, with the aim of providing its renovation project clients with an overview of the quality of installation projects actually achieved in this market.

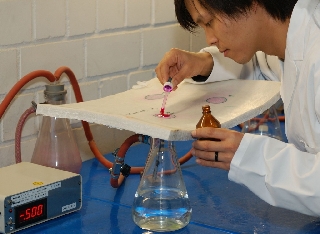

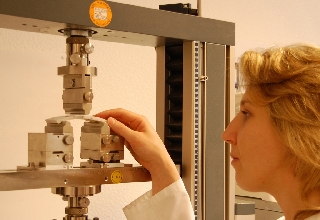

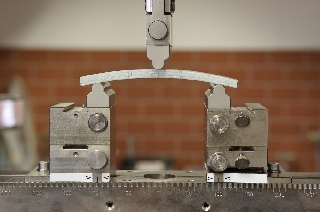

These reports evaluate CIPP liner samples obtained directly on-site. These samples are taken after curing of the liner and sent to the IKT laboratory, where IKT inspectors determine the important indicators of modulus of elasticity, flexural strength, wall thickness and water-tightness of the samples. A detailed assessment is then sent to the client.

But:

- What is the overall picture?

- Which contractors consistently perform high-quality work – everywhere, every time?

- What aspects require clients’ more detailed scrutiny?

Answers to these questions can be found in the IKT LinerReport, which is published at regular intervals, augmented with the results of the latest series of tests.

IKT’s LinerReport summarises individual test results to present an overall aggregated view. The primary objective is to ensure transparency and openness, in order that project clients know exactly which contractors achieve what levels of quality in their work.

IKT-LinerReport 2020: CIPP liners meeting target values at six-year low

No reason to be happy: the test results for watertightness dropped in comparison to previous years.

The overall test results for 2020 are the lowest in the past six years. One CIPP liner in eight did not achieve its expected target value for at least one test criterion. However, the requirement is clear and unambiguous: all four test criteria must be met simultaneously by a sample.

Downloads: English, German, Dutch, Japanese, Polski<!--, Francais, Polski-->, Chinese.

IKT LinerReport 2019: Seven Percent of Sewer Liner Samples do not Pass all Tests

93% of the sewer liner samples submitted for inclusion in the 2019 IKT LinerReport achieved all the required material characteristics. But, seven percent of samples failed at least one of the four tests. So there remains a residual risk.

For other languages please visit: www.ikt.de

<!--Download hier: Deutsch, English, Nederlands, Francais, Polski, český.-->

IKT LinerReport 2018: Has Trend for Improving Sewer Lining Quality Ended?

For more than ten years, the performance of CIPP liners continuously improved. But, in recent years the annual test results have sometimes been poorer. Is this a sign of a reversal in that trend?

For other languages please visit: www.ikt.de

IKT LinerReport 2017: The Need to Pass all Four Tests

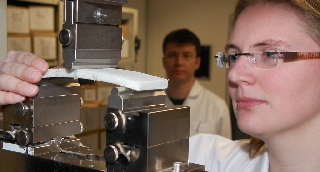

Under pressure: An IKT tester determines flexural strength at the point when a liner sample ruptures.

Too many liners still do not meet all four of the test criteria. They may pass individual criteria, but only those samples that pass all four can be considered really good.

IKT LinerReport 2016: Five Companies Qualify for ‘100% Club’

There were excellent CIPP liner results for the individual test criteria, but only one in four of the rehabilitation contractors succeeded in a 100% pass on all tests conducted on their samples. However, five years ago this figure was only one in five, so the overall trend is upward.

IKT LinerReport 2015: Slight Disappointment on Wall Thickness

CIPP-liner samples from six countries tested. Test results still at high level. Only wall thicknesses are more frequently below target. Most non-German companies also score well. For the first time, one company from the United Kingdom is included in the test programme.

IKT LinerReport 2014: Use of CIPP Liners Expanding in Europe

Liner quality continues to be high. Slight improvements over last year. CIPP lining gaining in importance in Europe, accompanied by increasing quality awareness. Liner Report 2014 includes Dutch, Austrian and Swiss results.

Ten years of the IKT LinerReport: Quality and Transparency Oblige

The IKT test centre has been publishing annual reports on the results of its CIPP liner tests since 2004. The tenth anniversary report considers:

- Are CIPP liners better today?

- What trends are apparent?

- And what is the current picture?

IKT-LinerReport 2011: CIPP Liner Quality Reaches Celebratory High Level!

The CIPP liner‘s 40th anniversary found the process in top form; the test results for 2011 are a significant improvement over the previous year‘s level.

IKT LinerReport 2010: CIPP Liner Water tightness Constantly Improving

Overall, the 2010 test results achieved a high level: water-tightness again improved, static test characteristics were still good, only the wall thickness results were poorer than last year.

IKT LinerReport 2008: CIPP Liner Quality: Variegated Trend

CIPP liners performance had improved across the board in 2007. However, in 2008 there were both improvements and deteriorations in performance. Where are the potentials for improvement in individual liner systems?

IKT LinerReport 2007: CIPP Liner quality in 2007: An Improvement over Last Year

A pleasing trend: This year’s IKT LinerReport is pleased to announce higher on-site quality levels. Test results have, on average, improved. The ongoing quality debate is starting to produce results.

IKT-LinerReport 2006: Glass Clearly Ahead?

- Is the material the only important factor in cured-in-place pipe rehabilitation?

- What quality standards do installers (contractors) achieve, and with which types of liner?

- The IKT-LinerReport 2006 paints a differentiated picture.

IKT-LinerReport 2004/2005: The Range is Widening

IKT presents for the second time a statistical evaluation of its CIPP liner database. The objective is enhanced transparency in rehabilitation quality control. In the 18 months that have passed since the first LinerReport was published, some trends have established themselves and new developments have appeared.

IKT Liner Report 2003/2004: Test Results from the Building Site

IKT tested samples of CIPP liners on several hundred building sites. The results of the IKT tests show how different renovation contractors fared.